Add to Cart

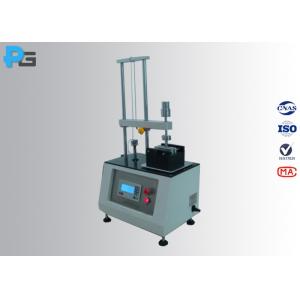

IEC60598-1 Clause 4.4.4 G5/G13 Lampholders Axial Force Test Device for Fluorescent Lamps

1. Introduction

The axial force test device is designed to test the lampholders (G5, G13, G23, G10q, GR8) for fluorescent lamps according to IEC60598-1 clause 4.4.4. It is applied to assess the fixing device of lamhpolder should have adequate mechanical strength so as to withstand rough handling as may be expected in normal use. The test should be checked by lampholders for fluorescent lamp with a test cap in position, a pressure applied to the center of the cap in the direction of its axis for 1 min. After the test, the distance between the holders shall comply with IEC60061-2 and the lampholder shall show no damage. The test cap for this test shall comply with IEC60061-3 (7006-47C for G5 lampholders, 7006-60C for G13 lampholders). The single-capped fluorescent lamps of the lampholder shall not have moved from its position and the fixing device shall show no permanent deformation, so that the lamp, when reinserted will come in its intended position.

2. Parameter

| Controller | PLC control+touch screen interface |

| Test station | 1 |

| Test driver | Stepping motor |

| Pressure apply method |

Free vertical pressure Manual adjust the center position |

| Test fixture | Self-tightening type, fit with G5, G13 and other lampholders |

| Pressure apply | 15N*1, 30N*1 |

| Dimension | 500mm*400mm*800mm (L*D*H) |

| Working power | 220V/50Hz |